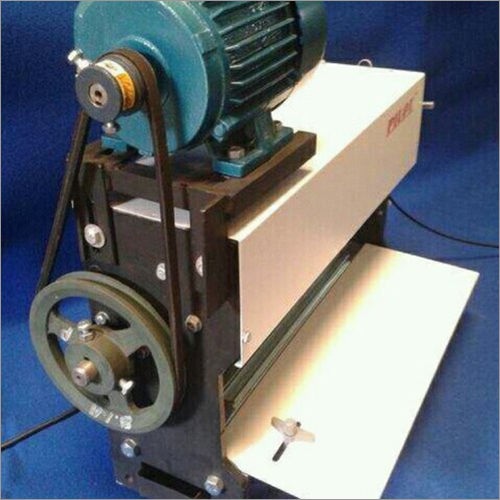

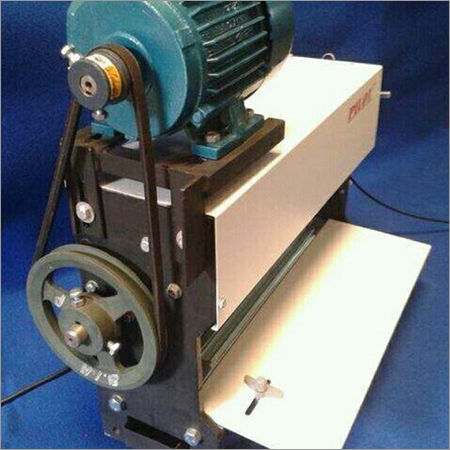

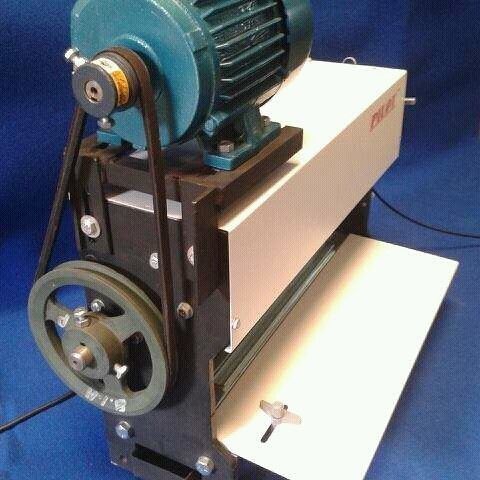

6*4mm Punch Automatic Electrical Wiro Binding Machine (2 In 1)

Product Details:

- Type Paper Binding Machinery

- Material Mild Steel

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Voltage 220 Volt (v)

- Power 0.5 Horsepower (HP)

- Click to View more

6*4mm Punch Automatic Electrical Wiro Binding Machine (2 In 1) Price And Quantity

- 34000 INR/Piece

- 1 Piece

6*4mm Punch Automatic Electrical Wiro Binding Machine (2 In 1) Product Specifications

- Paper Binding Machinery

- 80 Kilograms (kg)

- Mild Steel

- 220 Volt (v)

- 0.5 Horsepower (HP)

- Human Machine Interface

- No

- Automatic

- 29*18*27 Inch (in)

6*4mm Punch Automatic Electrical Wiro Binding Machine (2 In 1) Trade Information

- 7 Days

- All India

Product Description

A 6mm punch automatic electrical wire binding machine is a device designed to automate the process of punching holes and wire binding documents. Here's what you can expect from such a machine:

1. Automatic Operation As an electrically-powered device, this machine automates the hole punching process. You simply need to insert the paper stack into the machine, and it will automatically punch the holes at the specified intervals without requiring manual input.

2. 6mm Punch Size The 6mm punch size indicates the diameter of the holes that the machine creates in the paper. This size is standard for accommodating the wire spines used in wire binding. It provides a balance between hole size and document stability.

3. Wire Binding Capability The machine is specifically designed for wire binding, also known as twin-loop binding or double-loop binding. This binding method involves inserting a wire spine through the punched holes to bind the pages together. Wire binding allows the document to lay flat when opened and provides a professional appearance.

4. High Capacity Electric wire binding machines typically have a higher punching capacity compared to manual ones. They can handle larger stacks of paper, making them suitable for high-volume binding tasks.

5. Ease of Use Electric machines are designed for ease of use, with intuitive controls and automated processes that streamline the binding workflow. They're suitable for users of all skill levels.

6. Adjustability Many electric wire binding machines offer adjustable features such as margin depth and hole spacing, allowing you to customize the binding according to your preferences and the size of your document.

7. Portability While electric machines may be larger than manual ones, some models are still relatively compact and portable, making them suitable for use in various settings such as offices, print shops, and businesses.

When selecting a 6mm punch automatic electrical wire binding machine, consider factors such as punching capacity, adjustability, ease of use, and portability to ensure it meets your specific binding needs and workflow requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+