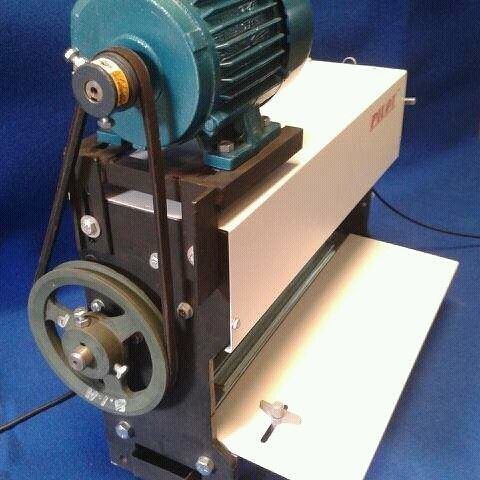

Wiro Closer Binding Machine

Price 7000.0 INR/ Piece

Wiro Closer Binding Machine Specification

- Type

- Paper Binding Machinery

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Manual

- Weight (kg)

- 15 Kilograms (kg)

- Dimension (L*W*H)

- 24*13*13 Inch (in)

Wiro Closer Binding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Wiro Closer Binding Machine

A Wiro closer machine is a device specifically designed for closing wire binding spines, also known as Wiro bindings. Here's an overview of its features and functions:

1. Closing Mechanism The primary function of a Wiro closer machine is to close the wire binding spines securely. These machines typically feature a mechanism that presses and bends the ends of the wire loops together, ensuring a tight and secure closure.

2. Adjustable Settings Many Wiro closer machines come with adjustable settings to accommodate different wire sizes and document thicknesses. Users can adjust the closing mechanism to achieve the optimal closure for their specific binding requirements.

3. Ease of Use Wiro closer machines are designed to be user-friendly, with intuitive controls and simple operation. They typically require minimal setup and training, allowing users to quickly and efficiently close wire bindings.

4. High Capacity Some models are capable of closing a large number of wire bindings in a short period, making them suitable for high-volume binding tasks in busy environments such as print shops or offices.

5. Accuracy Precision is crucial in wire binding to ensure a neat and professional finish. Wiro closer machines are engineered to provide consistent and accurate closure, resulting in uniform and aesthetically pleasing bound documents.

6. Safety Features Like any machinery, safety is paramount. Wiro closer machines may incorporate safety features such as guards or sensors to prevent accidents and injuries during operation.

7. Portability and Size Depending on the model, Wiro closer machines vary in size and portability. Some are compact and lightweight, suitable for small offices or on-the-go binding tasks, while others are larger and more stationary, suitable for heavy-duty binding operations.

Overall, a Wiro closer machine is an essential tool for efficiently and effectively closing wire binding spines, ensuring a professional and secure finish for bound documents.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wiro Binding Machine Category

4mm Punch Automatic Electrical Wiro Binding Machine (3 In 1)

Price 34000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Dimension (L*W*H) : 29*18*27 Inch (in)

Weight (kg) : 80 Kilograms (kg)

Computerized : No

4mm Punch Automatic Electrical Calendar Spiral Binding Machine

Price 36000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Dimension (L*W*H) : 29*18*27 Inch (in)

Weight (kg) : 80 Kilograms (kg)

Computerized : No

4mm Punch Automatic Electrical Calendar Wiro Binding Machine (3 In 1)

Price 35000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Dimension (L*W*H) : 29*18*27 Inch (in)

Weight (kg) : 80 Kilograms (kg)

Computerized : No

2 In 1 Heavy Duty Wiro Binding Machine

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Dimension (L*W*H) : 29*18*27 Inch (in)

Weight (kg) : 80 Kilograms (kg)

Computerized : No

Send Inquiry

Send Inquiry